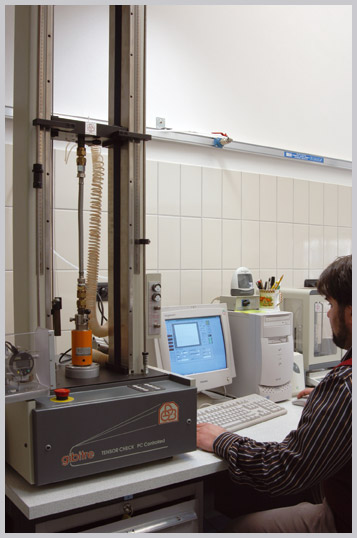

CERTIFIED QUALITY

An efficient internal Quality Control checks the processes and the raw materials used to guarantee a hig level of quality that remains constant in time. The checks are made in the internal Laboratory that is provided with all the equipment needed to check the individual components and the finished products. In 2005 our Company obtained ISO 9001:2008 Certification for Qulity Management System and, over the last few years, has obtained the principal European Product Certfications for flexible pipes.

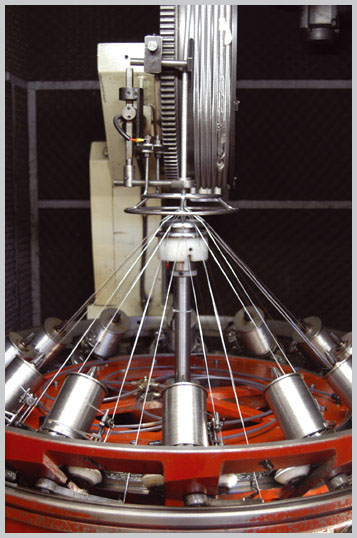

AVANT-GUARDE AND ACCURACY

The production departments are divided into 3 sectors: the turning department, the braiding department and assembly.

A modern department equipped with multi-spindle and CNC lathes allows the production of the whole requirement of pipe fittings, in brass or steel, used for internal production. The high level of flexibility allows all client requests to be met in temrs of quantity and quality, including when making special articles on drawing.

The braiding department, for the production of braided pipes with steel, aluminuim or textile wires, uses automatic braiding and winding machines of recent manufacture, chosen from among the most technically advanced models offered by the market in the sector.

Assembly of the flexible pipes is done exclusively with the use of automatic systems and semi-automatic machinery built internally. The design and production of these system come from the considerable experience acquired over the years and represents everything that is most advanced, in terms of productivity and quality, that can be found in the flexible pipe sector.